Highest quality, lowest budget, complete turnkey project are the benefits for the customer.

Highest quality, lowest budget, complete turnkey project are the benefits for the customer.

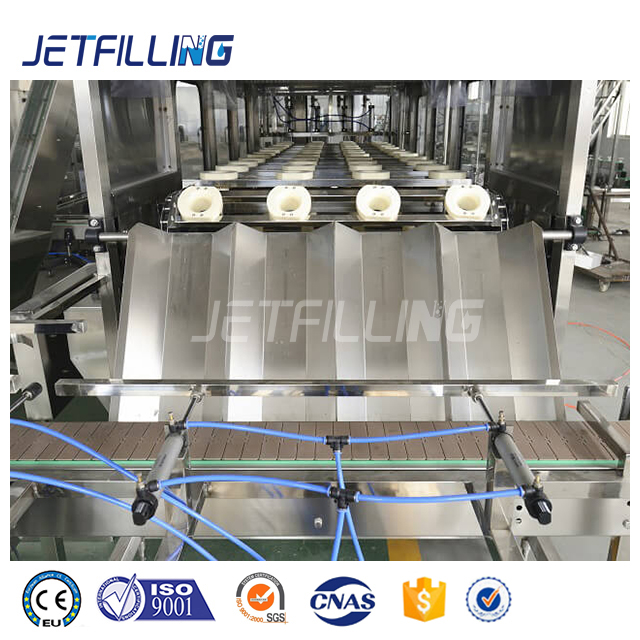

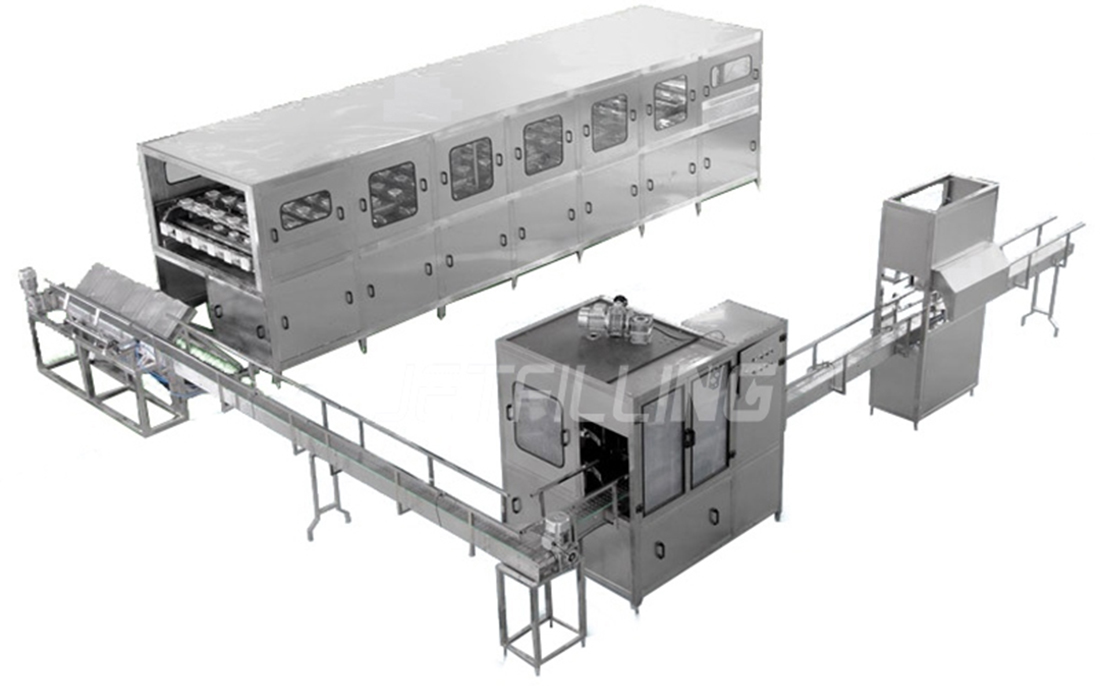

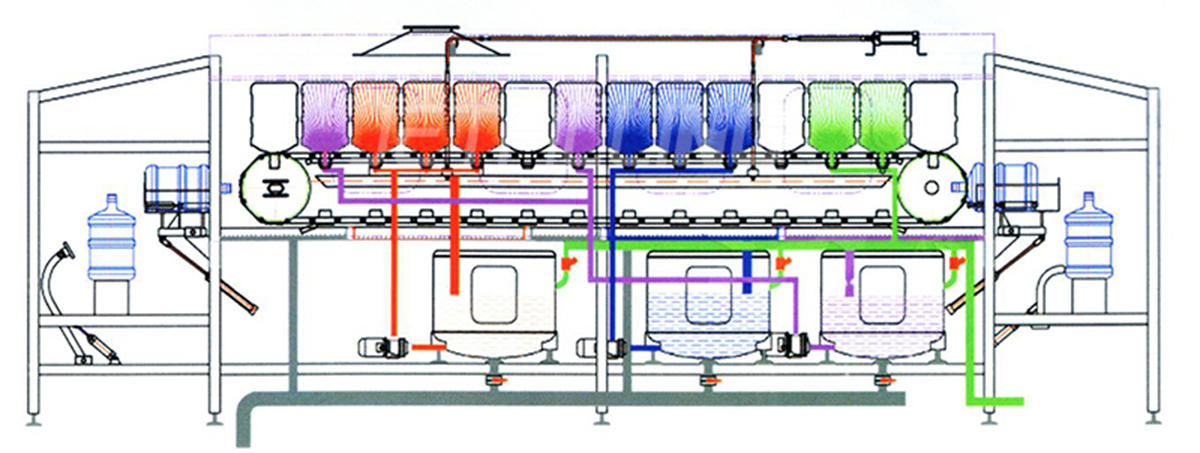

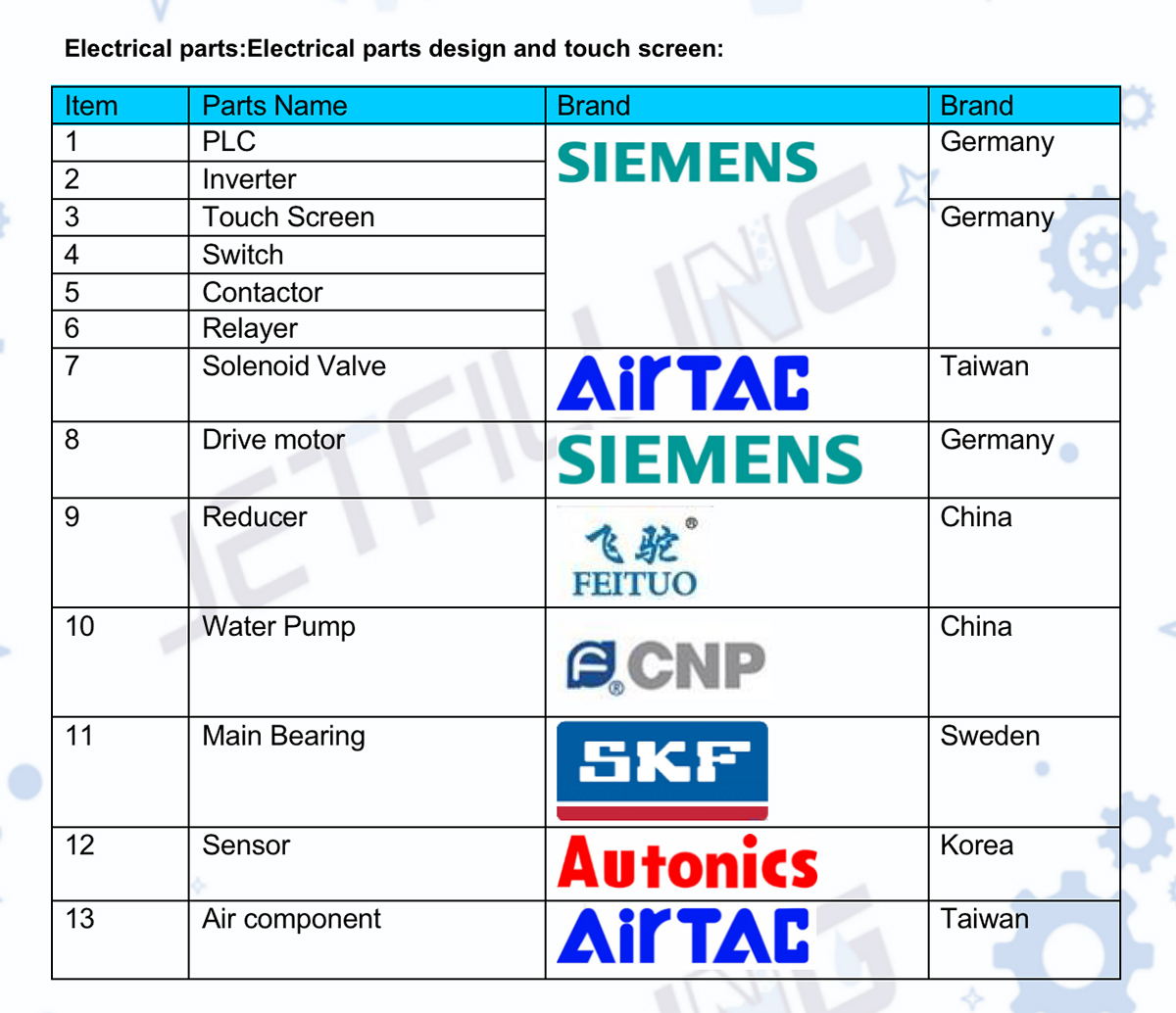

The 5 gallon barreled water filling machine is composed of washing, filling and sealing. The bottle washing machine uses multiple washing liquid sprays and disinfectant spray to achieve the purpose of washing and disinfecting, and the disinfectant can be recycled. The sealing machine can be automatically sealed and equipped with a shower device during the delivery of the cap to ensure that the cap is sterile and clean. The filling machine can automatically wash, disinfect, fill, gland, count and output. It has the features of complete functions, novel design and high degree of automation. It is a new type of bottled water filling equipment integrating machine, electricity and gas.

5 Gallon Filling Machine

The 5 gallon barreled water filling machine is composed of washing, filling and sealing. The bottle washing machine uses multiple washing liquid sprays and disinfectant spray to achieve the purpose of washing and disinfecting, and the disinfectant can be recycled. The sealing machine can be automatically sealed and equipped with a shower device during the delivery of the cap to ensure that the cap is sterile and clean. The filling machine can automatically wash, disinfect, fill, gland, count and output. It has the features of complete functions, novel design and high degree of automation. It is a new type of bottled water filling equipment integrating machine, electricity and gas.

One partner for all your needs.

A gallon bottle filler/ 20L water filler/ Gallon Filling plant from JETFILLING takes into account every step of your water filling process, from minimising resource waste to determining your bottle's ideal look and weight. With everything centred around one supplier, you get wide-ranging expertise, line equipment and ongoing services. This ensures high quality and efficiency from packaging to equipment, fast ramp-up and beyond.

| Technical parameter :5 gallon filling machine | |||||

| Model | QGF-100 | QGF-300 | QGF-450 | QGF-600 | QGF-900 |

| Filling heads | 1 | 2 | 3 | 4 | 6 |

| Power of main motor | 0.37KW | 0.6KW | 0.8KW | 1KW | 1.5KW |

| Total weight | 680kg | 1500kg | 2100kg | 3000kg | 3500kg |

| Capacity | 100 | 300 | 450 | 600 | 900 |

| Dimension | 500*4000*1500 | 900*4000*1500 | 1300*4000*1500 | 1800*4000*1500 | 2400*4000*1500 |

Different filling capacities:

5 Gallon Water Filling Machine

This machine is driven by cylinder, controlled by PLC; Automatic working by barrel checking;De-capping head is composed by claw device and cylinder, de-capping head position can move up and down, claw device can be adjusted slightly to be suitable for different caps. When the gallon bottle comes into the machine, the de-capping head will go down and claw device will hold tightly barrel cap sides, and then lift the barrel to take off the caps; And when the caps are taken off, the compressor air will blow the caps into cap hopper, then fall outside into client’s own holder; The claw pressure is adjusted to protect caps;

| Outside Brush of 5 gallon filling machine The 5 gallon bottle outside washing machine was used for brushing the 5 gallon bottle outside, the machine was used for used bottle mainly.The brush washing progress is automatic. The square external brush of the external barrel-washing machine consists of three parts. |

Washer of 5 gallon filling machine The bottle washer adopts multi-channel washing liquid injection and disinfectant injection for the purpose of washing sterilization.The disinfectant is recyclable. |  |

More products details

|  |  |

Main Features

|

|

|  |

|

Containerization – International shipments require greater care and protection than domestic shipments. As an important factor in the global trade industry, containerization protects the shipment inside the container from humidity and extreme freezing temperature. The benefits of containerization include:

1.Reduced loss and damage cost 2.Lower transportation and warehouse cost due to easy storage and transportation of containers 3.Can be used to temporarily store your equipment

|  |  |

Half-finished products and spare parts are well prepared

Mass production of semi-finished products and parts can ensure that the equipment required by most customers can be completed within one month!

|  |

The whole production will be connected and test running in factory

Before leaving the factory, each device will be tested many times to ensure that there is no problem with each device that customers get!

By continuing to use the site you agree to our privacy policy Terms and Conditions.