Have any questions! Don't hesitate to contact us any time.

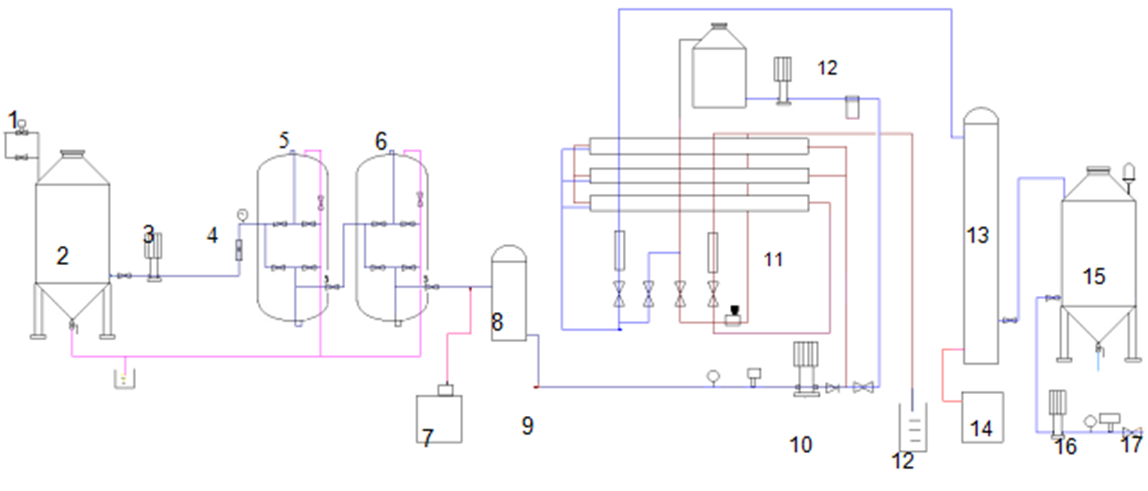

Water

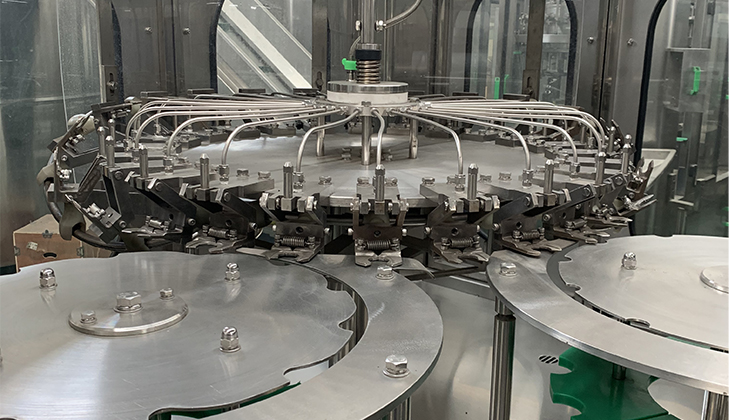

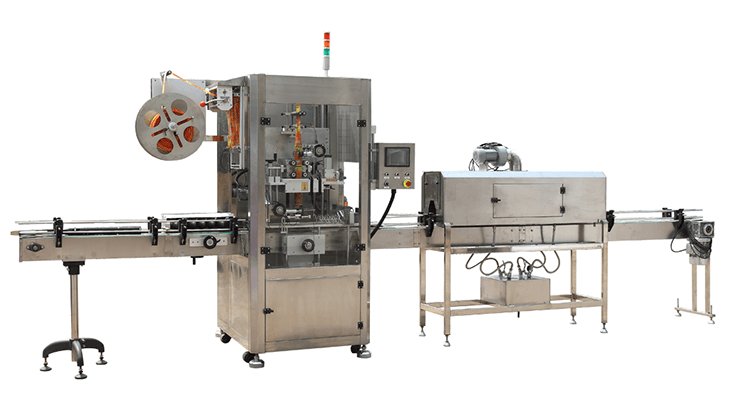

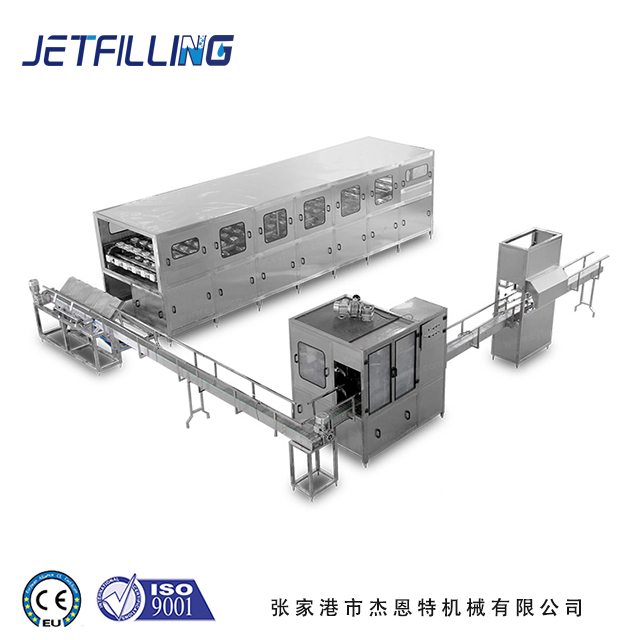

water filling machine

Water Machinery can finish all the process such as washing bottle, filling and sealing, it can reduce the materials and Outsiders touch time, improve the sanitary conditions, production capacity and economic efficiency.